Composite Sheet

3M™ Fire Barrier Composite Sheet CS-195+

ผลิตภัณฑ์ป้องกันไฟลาม

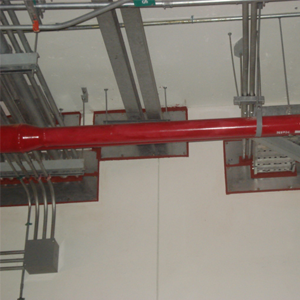

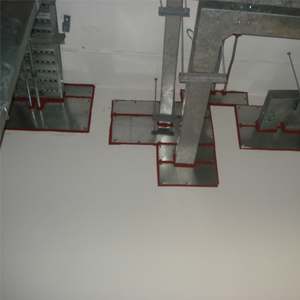

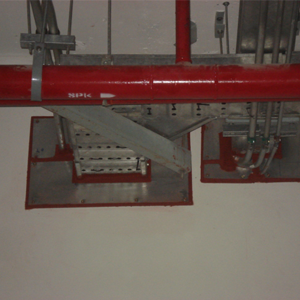

- Four-component intumescent system is ideal for firestopping larger penetrations such as cable trays and conduit

- Forms effective intermittent fire-break within horizontal and vertical cable tray runs

- Hard char material tightly seals penetrations against flame spread, smoke and toxic gases

- Easy to install: cut, form and install using common trade tools for nearly any size

- Thermally conductive: allows unwanted heat build-up to escape, helping reduce derating issues

- Re-enterable for new or retrofit installations

- Firestop tested for up to 4 hours in accordance with ASTM E 814 (UL 1479)

Features

3M™ Fire Barrier Composite Sheet CS-195+ is a lightweight intumescent firestop that combines four components into a single system to help slow the spread of fire, smoke and noxious gases. Sheets combine 28-gauge steel, intumescent material, wire mesh and aluminum foil and are easy to handle and install with common trade tools. They are firestop tested for up to 4 hours of fire protection.

- Intumesces (expands with heat) to form a hard char that tightly seals penetrations against flame spread, smoke and toxic fumes.

- Multiple applications…through penetration firestop, heat shield and firebreak protection.

- Easy to install using common trade tools.

- Lightweight…easy to handle, cut and form to desired shape.

- Easy to fasten…bolt punch or drill through. Use self-tapping screws or anchor bolts.

- Thermally conductive…allows unwanted heat build-up to escape.

- Non-flame supporting.

- UL Classified.

- Cost effective, high performance versus installed cost.

- No mixing or damming…is clean to install.

- Versatile: can be cut to fit irregular shapes.

- Re-enterable.

- Low odor.

- Normal disposal procedures.

Specifications

The intumescent sheet must be capable of passing ASTM E 814 (ANSI/UL 1479) Standard Method of Fire Tests for Through-Penetration Fire Stops up to the desired fire resistance rating.

All penetrations in fire rated walls, floors, floor ceiling assemblies and designated smoke or fire barriers shall

be sealed with 3M Brand Fire Barrier Products per manufacturers installation instructions.

Sheet Sizes:

28 in. x 52 in. (711,2 mm x 1320,8 mm)

24 in. x 36 in. (609,6 mm x 914,4 mm)

36 in. x 36 in. (914,4 mm x 914,4 mm)

36 in. x 41 in. (914,4 mm x 1,041 mm)

16 in. x 28 in. (406,4 mm x 711,2 mm)

Performance

A.Physical and Electrical Properties

Nominal Weight (lb/ft2) 2.75 : (13,4 kg/m2)

Fire resistive ratings : up to 4 hours

[ASTM E 814 (UL 1479)]

Expansion begins : 302°F (150°C)

Significant expansion : 350°F (177°C)

Weight loss (TGA) : 20.1% @ 662°F (350°C); 31.0% @ 932°F (500°C); 53.2% @ 1,832°F (1000°C)

Expansion : 8-10 typical

Dielectric strength : 119 volts/mil average

(ASTM D 149)

Non-flame supporting hardness : 45 to 65 Shore A

Tensile strength/elongation : 93.6 psi (0,645 MPa)/489%

(ASTM D 412, Method A)

Compression : set 25% (maximum)

B.Fire Performance Test

1.Summary of Fire Test Results per

ASTM E 814 (ANSI/UL 1479)

2. Summary of Fire Test Results per

ASTM E 814, Electrical Circuit

Protection Systems for Cable Trays

3. Surface Burning Characteristics

ASTM E 84 (ANSI/UL 723)

1.Up to 4 hour ratings for penetrations in walls and floors. See current UL Fire Resistance Directory.

2.1 hour UL Classified Systems. See Current UL Buildings Material Directory.

3.Flame Speed 5 Smoke Development 50