Carbon Dioxide Suppression Systems

Carbon dioxide (CO2) is a colorless, odorless, and chemically inert gas that is both readily available and electrically non-conductive. It extinguishes fire primarily by lowering the level of oxygen that supports combustion in a protected area. This mechanism of fire suppression makes CO2 suppression systems highly effective, requiring minimal clean-up, but should be used in normally unoccupied hazard locations or otherwise avoided by personnel when discharged. CO2 suppression systems may utilize the gas through a total flooding approach but carbon dioxide is also the only gaseous agent that may be utilized through local application. Carbon dioxide may be stored in either high pressure spun steel cylinders (HPCO2 suppression systems) or low pressure light wall refrigerated tanks (LPCO2 suppression systems).

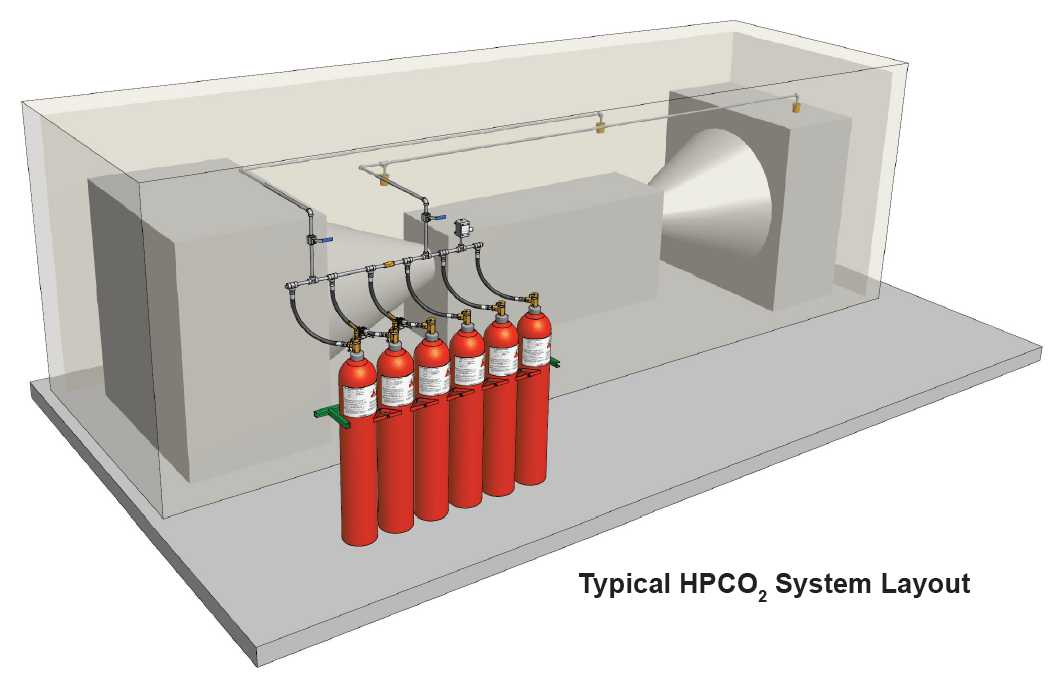

HPCO2 Fire Extinguishing System

The Janus Fire Systems® HPCO2 Fire Extinguishing System utilizes highly pressurized carbon dioxide as the extinguishing medium. Carbon dioxide (CO2) is a dry, inert, non-corrosive fire suppression agent perfectly suited to protect high value assets in normally unoccupied and unoccupiable areas when an electrically non-conductive agent is required and where clean-up of other agents is problematic. Each system consists of the following components and their associated accessories:

1. HPCO2 Storage Components

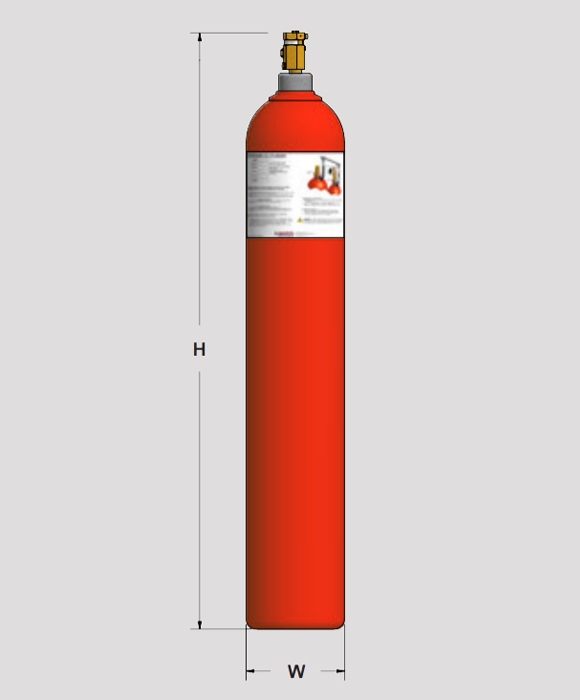

Storage components consist of the cylinder assembly(s), which contains the liquid CO2 agent, and the cylinder bracket(s), which holds the cylinder assembly securely in place.

2. HPCO2 Distribution Components

Distribution components consist of the discharge nozzles used to introduce the CO2 agent into a protected hazard along with the associated piping system used to connect the nozzles to the cylinder assembly.

3. Trim Components

Trim components complete the installation of the HPCO2 system and consist of discharge flex hose, discharge outlet adapters or check valves, actuation flex hose, connection fittings, solenoid valves, and manual valve actuators.

4. Supplemental Components

Supplemental components include the discharge pressure switch, inline check valves, selector valves, lockout valves, rupture discs, and regulators. They supplement the core equipment or complete a specific cylinder configuration.

5. Control Panel

This device monitors the condition of the solenoid valve, detectors, warning devices, and any manual release stations. All electric or electronic devices must connect to the control panel in order to function.

6. Early Warning Detection and Alarm Devices

Early warning detection devices coupled with manual release stations maximize system efficiency while audible and visual alarm devices alert staff of alarm conditions.

EQUIPMENT DESCRIPTION

Trim components are required to operate a single HPCO2 cylinder.

CYLINDER MOUNTING

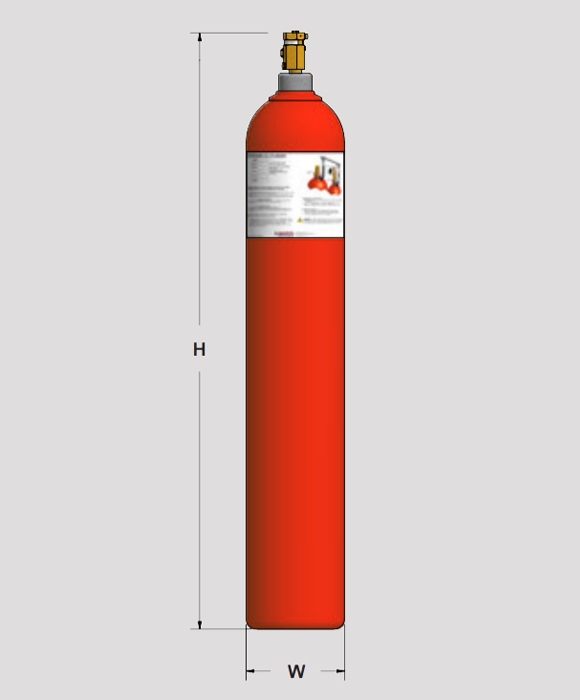

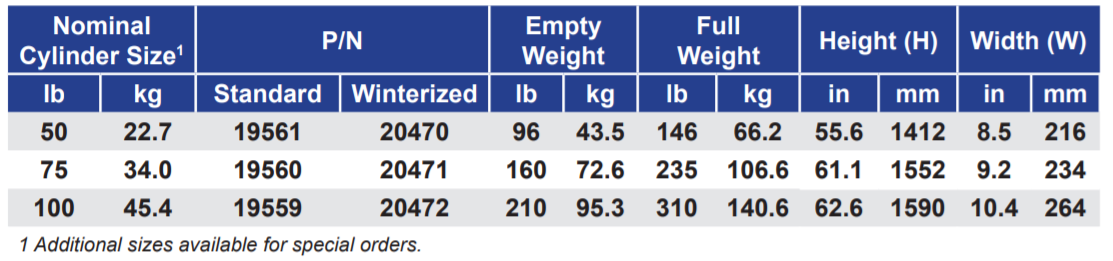

The CO2 agent is stored as a liquid in cylinder assemblies designed specifically for this purpose and pressurized to 850 psi (58.6 bar) at 70°F (21°C). An identification label is affixed to the cylinder body indicating the empty cylinder weight, filled cylinder weight, fill quantity of CO2, charging pressure, date of fill, and fill station. Except for special temperature conditions, all cylinders are filled to their specified weight. Winterized cylinders are filled to 90% of their capacity with carbon dioxide and then superpressurized with nitrogen to the remaining full capacity in order to prevent cylinder pressure from dropping below 750 psi (51.7 bar) in extremely cold environments. Cylinders are not partially filled.

Click to download Datasheet:

TRIM COMPONENTS

Trim components are required to operate a single HPCO2 cylinder.

The cylinder assembly is composed of a cylinder, dip tube, and cylinder valve.

Cylinder Valve:

The automatic release of CO2 is controlled by a forged brass, force differential operated cylinder valve connected to the neck of the cylinder. Each valve assembly is shipped with an anti-recoil safety plug installed in the discharge outlet and a

manual actuation safety plug installed in the manual actuation connection. Both safety plugs are chained to the cylinder valve.

Dip Tube: A rigid dip tube is used in all cylinders to ensure liquid discharge.

Cylinder: The seamless cylinder is manufactured according to the requirements of the U.S. Department of Transportation (USDOT) and/or Transport Canada for compressed gas. The cylinder is designed for mounting in a vertical position only.

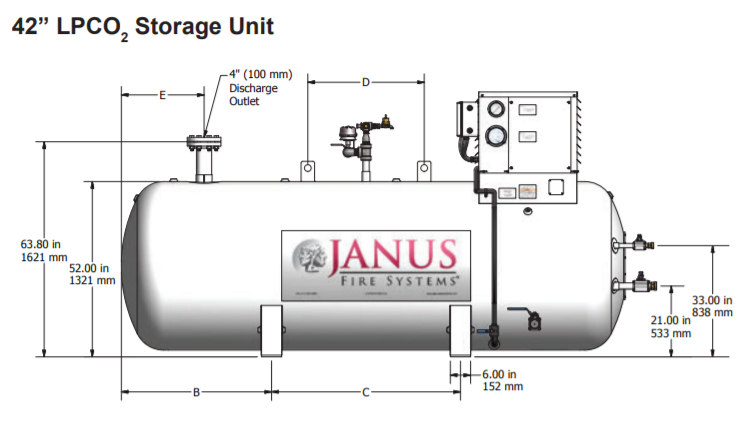

LPCO2 Storage Units

Janus Fire Systems® Low Pressure CO2 Storage Units consist of an insulated ASME VIII pressure vessel, steel outer shell, integrated refrigeration unit, ASME safety relief and bleeder valve(s), and liquid level and pressure gauges. Storage units are available in capacities ranging from 1.25 ton (1.13 metric ton) to 50 ton (45.4 metric ton).

LPCO2 Pilot Cabinets

Janus Fire Systems® LPCO2 Pilot Cabinets operate in conjunction with system valves, alarm and detection, and LPCO2 storage units to discharge the CO2 system while incorporating pneumatic time delays and sirens where required by NFPA 12.

TYPICAL AREAS OF FIRE PROTECTION

- Flammable Liquid Storage

- Transformers

- Rotating Electrical Equipment

- Metal Processing Facilities

- Printing Industry

- Paint Mix

- Machining Facilities